In today's world, it is crucial to ensure our hobbies and business practices don't harm the planet. Much like tending an organic garden in your backyard, choosing sustainable methods for DTF (Direct-to-Film) printing can significantly impact without sacrificing quality or creativity. These informed choices align our values with our actions, leading us toward a more responsible lifestyle.

Adopting eco-friendly DTF printing doesn't complicate your processes; it simplifies them while protecting the environment. We make strides towards a greener future by reducing harmful chemicals, lowering emissions, and using sustainable materials. Such careful consideration guarantees that your personalized projects are beautiful and responsibly produced. This exploration reveals why understanding DTF basics and its eco-benefits is vital for anyone committed to sustainability.

Sustainable practices in Eco-Friendly DTF Printing can include using eco-solvent inks that reduce volatile organic compound emissions and reusable transfer film and ink to minimize waste. Additionally, choosing water-based inks over solvent-based inks is an environmentally friendly option that reduces VOC emissions into the air.

Introduction to DTF Printing

Direct-to-Film (DTF) printing is an innovative method for transferring designs onto fabric, offering remarkable durability and vibrancy without requiring extensive setup or equipment. Unlike some traditional methods, DTF excels in producing vivid, long-lasting prints on various textiles.

The heart of DTF printing lies in the heat transfer process, which involves using special water-based inks and PET films coated with polymer to receive the inks. This unique combination allows for a seamless transfer of intricate designs onto fabric, ensuring excellent adhesion and durability. Using these materials contributes to the sustainability of the process, making it an attractive option for environmentally conscious individuals and businesses.

Moreover, DTF printing's versatility is worth noting as it works seamlessly on various textiles such as cotton, polyester, and blends. This flexibility has made it a favorite within the bespoke apparel and custom merchandise market. Designers and manufacturers appreciate its ability to accurately reproduce complex designs and even photographic images, unlocking a world of creative possibilities.

For instance, were you envisioning a custom t-shirt adorned with intricate graphics or a personalized hoodie featuring a stunning photographic print? DTF printing offers the versatility needed to bring these visions to life, allowing you to express your creativity without compromising quality or sustainability.

As we journey deeper into the realm of eco-friendly DTF printing, it's imperative to explore the specific environmental benefits that this sustainable practice offers. Let's dive into the positive impact that DTF printing can have on our planet's future.

Environmental Benefits of DTF Printing

DTF printing presents a range of environmental advantages, positioning itself as a sustainable choice for the printing industry.

Reduced VOC Emissions

In comparison to traditional solvent-based inks, DTF printing employs eco-solvent inks, which emit fewer volatile organic compounds (VOCs). This reduction plays a vital role in minimizing air pollution.

VOCs are harmful chemicals that can evaporate into the atmosphere, contributing to smog formation and air pollution. By choosing DTF printing, you're actively reducing the release of these harmful emissions into the environment. This not only benefits the immediate surroundings but also has a positive impact on larger ecological systems and public health.

Lower Carbon Footprint

DTF printing's energy efficiency results in decreased carbon dioxide emissions during printing and heat transfer processes. This is pivotal for reducing the overall carbon footprint associated with print production.

Traditional printing processes are often energy-intensive, causing higher carbon emissions. Embracing DTF printing allows businesses to significantly reduce their environmental impact through sustainable and efficient production practices.

Minimum Chemical Usage

In contrast to traditional screen printing, which may necessitate using harmful chemicals for cleaning and dyeing, DTF printing involves fewer toxic substances. This shift aligns with eco-conscious practices crucial for a greener future.

Considering the global concern about hazardous chemicals in various industries, especially in textile manufacturing, DTF printing serves as an eco-friendly alternative. Its minimal chemical usage ensures a safer working environment and reduces potential risks posed to the surrounding ecosystem.

By recognizing these environmental benefits of DTF printing, businesses can actively contribute to sustainable practices, creating a positive impact on a larger scale. The utilization of eco-solvent inks, reduction in energy consumption, and minimized chemical usage collectively pave the way for a greener future within the printing industry.

As we continue exploring sustainable practices within the printing industry, let's turn our attention to the specific components that make eco-friendly inks and materials an integral part of DTF printing.

Eco-Friendly Inks and Materials

When it comes to eco-friendly DTF printing, one of the primary contributing factors is the use of water-based inks. Unlike solvent-based alternatives, water-based inks significantly reduce environmental hazards and emit fewer pollutants. These inks are also biodegradable, providing a more environmentally friendly option for printing on various surfaces. By opting for water-based inks, DTF printing minimizes its impact on the environment while maintaining high-quality results.

Additionally, reusable transfer films are another notable aspect of eco-friendly DTF printing. Unlike single-use materials that contribute to excessive waste, PET films used in DTF printing can be reused multiple times. This practice reduces the volume of waste generated and promotes a sustainable approach to material usage. By incorporating reusable transfer films into the printing process, DTF printing aligns with eco-conscious practices, emphasizing responsible resource utilization and waste reduction.

Moreover, sustainable sourcing plays a vital role in ensuring the environmental sustainability of materials used in DTF printing. At dtfnewengland.com, materials such as eco-friendly inks and films are sourced sustainably, adhering to stringent environmental standards. By prioritizing sustainable sourcing, DTF printing endeavors to minimize environmental impact throughout the supply chain, from raw material extraction to production and utilization. This commitment to sustainable resourcing reflects a conscientious approach to environmental preservation and responsible business practices.

In embracing water-based inks, reusable transfer films, and sustainable sourcing practices, eco-friendly DTF printing promotes an environmentally conscious ethos that extends beyond mere print production. With an emphasis on reducing environmental hazards, minimizing waste generation, and ensuring sustainable material utilization, this approach aligns with the overarching goal of fostering a greener future through mindful printing practices. Now, let's explore energy-efficient printing techniques that complement eco-conscious DTF printing principles.

Energy-Efficient Printing Techniques

The shift towards eco-friendly practices goes beyond the choice of inks and materials. Energy efficiency is another key consideration that directly impacts the sustainability of DTF printing. Let's explore why low energy consumption, advanced heating technology, and sustainable production design are vital aspects of eco-friendly DTF printing.

Low Energy Consumption

As environmental consciousness continues to shape industry practices, the demand for energy-efficient solutions has grown significantly. DTF printing systems stand out as energy-saving alternatives to traditional methods, such as screen printing, which involves multiple energy-intensive stages. DTF printing minimizes its carbon footprint by utilizing lower electrical power while still delivering high-quality results.

Low energy consumption reduces energy usage and translates to business cost savings. As operational costs decrease, companies can allocate resources more efficiently while contributing to environmental preservation. The cumulative effect of numerous businesses adopting energy-efficient DTF printing substantially reduces overall energy consumption within the apparel industry.

Advanced Heating Technology

The innovation in heat transfer techniques within DTF printing plays a pivotal role in optimizing energy expenditure. Unlike conventional printing methods that may require prolonged heating periods, DTF printing incorporates innovative heat transfer technologies to facilitate quick and efficient adhesion of inks to films. This reduces the printing process's duration and minimizes overall energy consumption, aligning with sustainable and eco-friendly principles.

Moreover, the precise control and distribution of heat during the transfer process enhance the print quality and durability while conserving energy. This dual benefit underscores the significance of advanced heating technology in promoting both environmental sustainability and quality output within the DTF printing domain.

Sustainable Production Design

An integral component of energy-efficient DTF printing lies in sustainable production design. Many DTF printers, including those used by dtfnewengland.com, have incorporated eco-conscious designs prioritizing energy efficiency. From streamlined operational processes to optimized equipment functionality, these sustainable production designs contribute to lower operational costs and reduced environmental impact.

By integrating energy-efficient design elements into their production processes, DTF printing providers actively align with sustainable ideals while supporting businesses in mitigating their environmental footprint. The collaborative effort to integrate sustainable production design into modern DTF printing not only enhances operational efficiency but also fosters a greener future for the apparel industry as a whole.

As we continue our journey towards creating a more sustainable approach to custom apparel production, let's dive into strategies for reducing waste in printing processes.

Reducing Waste in Printing Processes

When it comes to eco-friendly DTF printing, one of its most significant advantages is the reduction of waste during the printing process. Let's break down the key factors contributing to the reduction of waste.

Precision Printing

One of the noteworthy features of DTF technology is its ability to allow for precise print runs. This means only the exact amount of ink and film needed is used during production, minimizing leftover stock. Unlike traditional printing methods, where overproduction often leads to excessive material waste, DTF printing ensures that resources are utilized efficiently and effectively.

By accurately calculating the required ink and film for each print run, DTF substantially reduces the surplus or excess materials that would otherwise end up as waste. This precision benefits the environment by curbing unnecessary resource consumption and presents a cost-effective advantage for businesses. Reduced material waste comes with decreased production costs, making DTF printing an attractive option for sustainable and economically viable printing practices.

Remnant Recycling

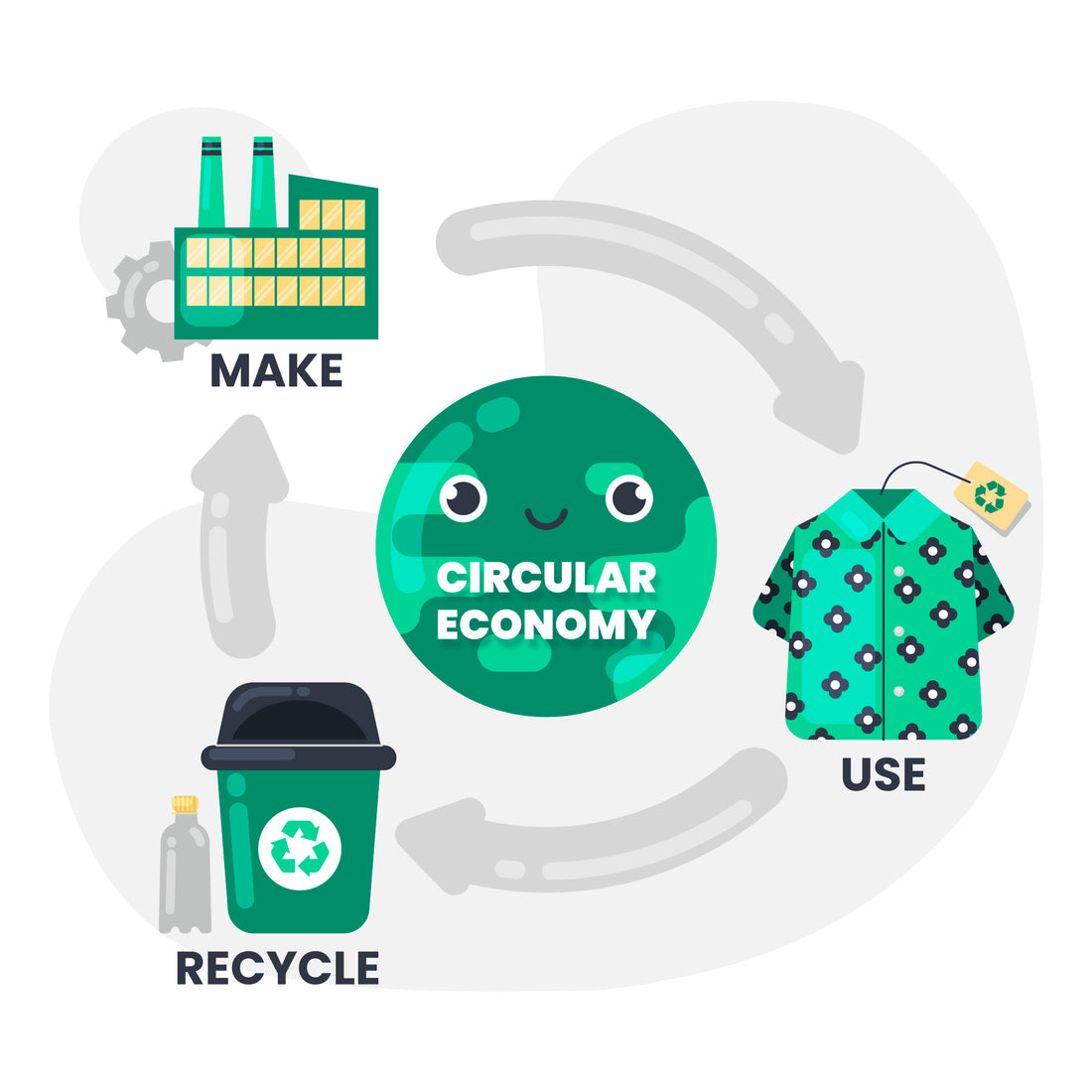

Even in the most resource-efficient printing processes, remnants may still be generated, such as excess film or discarded prints. However, with DTF printing, these remnants do not have to contribute to landfill waste. Instead, they can be recycled, thereby supporting waste management efforts and promoting a more sustainable approach to handling printing by-products.

Recycling remnant materials aligns with circular economy principles—a system aimed at minimizing waste and maximizing resource use efficiency. By repurposing materials such as excess film and discarded prints, the environmental impact of printing activities can be significantly reduced, paving the way for a greener and more sustainable future.

Digital Printing Advantages

Another crucial aspect of DTF technology is its digital nature. Unlike traditional printing processes, which require pre-press setups involving trial runs and test prints, DTF eliminates the need for such preliminary steps. By doing so, DTF minimizes the waste typically generated in traditional printing processes while streamlining production operations.

This digital advantage substantially reduces time, materials, and energy expended during the printing process. Without the necessity for pre-press setups and wasteful trial runs, DTF technology optimizes resource utilization and mitigates environmental impact. Furthermore, businesses employing DTF benefit from improved operational efficiency, cost savings, and a reduced ecological footprint—a testament to the multifaceted advantages of eco-friendly DTF printing practices.

By leveraging precision printing, embracing remnant recycling practices, and harnessing the advantages of digital printing, eco-friendly DTF technology stands at the forefront of sustainable printing methods—a beacon for environmentally conscious businesses seeking to minimize waste while maximizing operational efficiency.

As we look ahead to advancements in sustainable printing technologies, it's imperative to comprehend their potential impact on reshaping our environmentally conscious practices in various industries.

Future of Sustainable DTF Technologies

An array of innovative advancements and the increasing demand for sustainable practices illuminate the path to an eco-friendly future in DTF printing. The continuous progression of DTF technologies is steering this industry toward greener and more efficient solutions.

One significant trajectory in sustainable DTF technologies is the incorporation of automated processes. Automation not only increases efficiency but also minimizes human error, leading to reduced material waste and energy consumption. With precise and accurate printing processes, the need for reprints due to errors is minimized, resulting in less material wastage and a more sustainable approach overall.

Moreover, developing biodegradable films and inks is a game-changer for eco-conscious DTF printing. These environmentally friendly materials mitigate the environmental impact of traditional printing practices, offering a viable alternative that aligns with sustainability initiatives.

As these advancements gain traction, more businesses recognize the value of integrating sustainable DTF practices into their operations. The escalating awareness of environmental concerns and the growing demand for greener solutions across various industries spurs the adoption of eco-efficient DTF printing methods.

The market isn't just responding to a trend—it's embracing a necessary shift towards sustainable practices that prioritize environmental responsibility without compromising quality. Businesses align with eco-friendly strategies to meet consumer expectations while fulfilling corporate social responsibilities.

Industry leaders like DTF New England are at the forefront of this paradigm shift, advocating for sustainable practices through responsible sourcing and energy-conscious technology.

In a world grappling with climate change challenges, the convergence of technological advancements, market adoption, and industry initiatives heralds a promising prospect for greener DTF printing practices. By leveraging sustainable technologies and fostering a culture of environmental stewardship, the future of DTF printing is poised to withstand the test of time while significantly reducing its ecological impact.

In Summary

The future of sustainable DTF technologies revolves around technological innovations, market adoption of eco-efficient practices, and industry initiatives driving positive change towards greener solutions. As businesses prioritize sustainability and environmental responsibility, the trajectory of DTF printing is set on a course that embraces eco-friendly practices without compromise.

The future of eco-friendly DTF printing holds great promise for both the environment and businesses alike.